Our products are being developed for mass production and will eventually be available for sale. If you are an interested buyer, a potential community client, or an entrepreneur looking to help with development, please contact us.

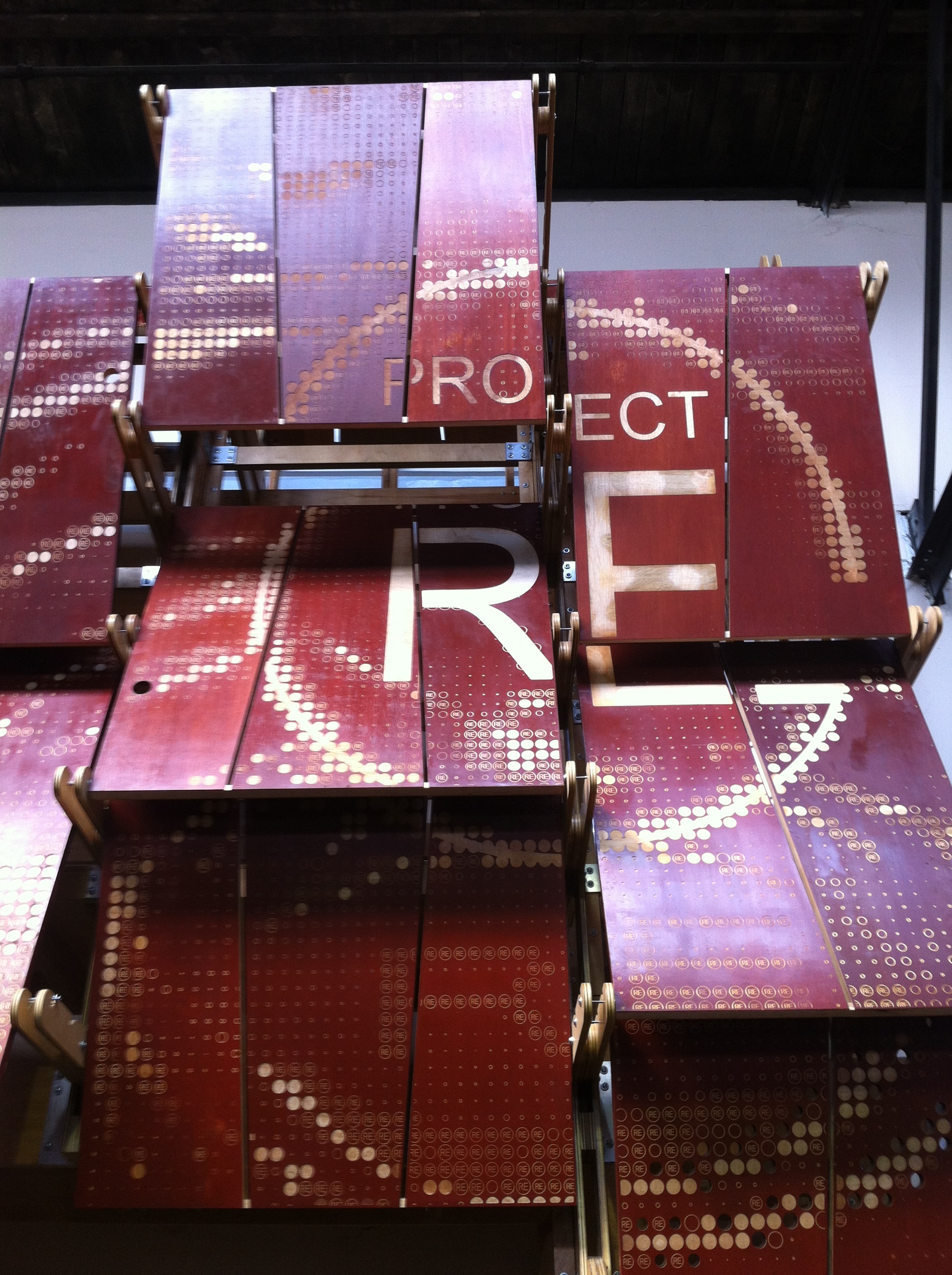

PROJECT RE_ FACILITY

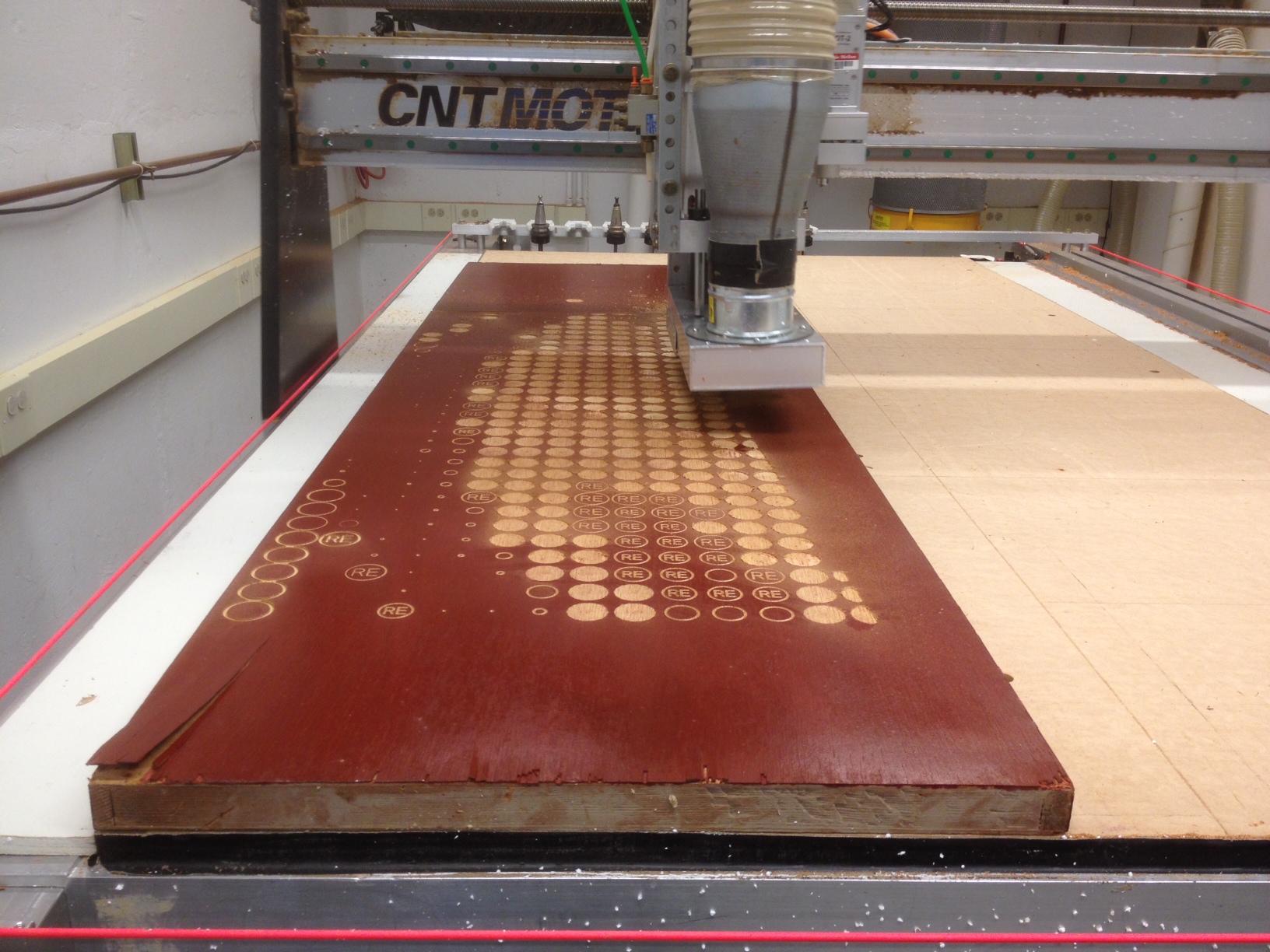

The three year design and construction process involved close collaboration between students, clients, stakeholders, and consultants. UDBS students were asked to develop products featuring reused materials and public interest programs simultaneously. The design is firmly grounded in the physical limits of what can be made with hands and knowledge bases in training. TIP apprentices assisted with construction as an exercise in learning and honing their carpentry skills.

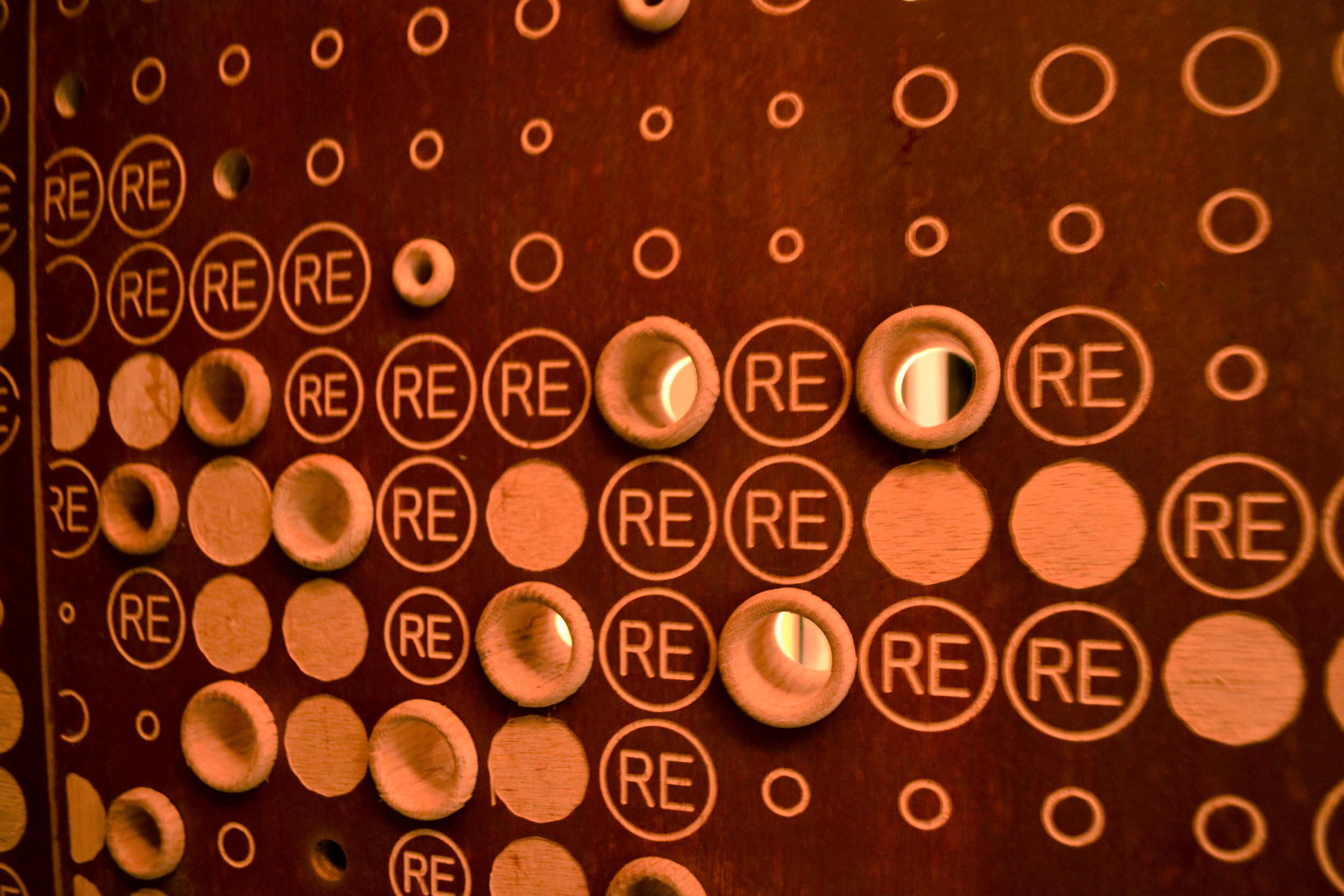

Additionally, the building demonstrates the value of deconstruction and material reuse as waste reduction strategies. CJ identified underutilized items and students invested time in designing processes for giving them new life. Each system employs reused materials in scalable, marketable building products that can be mass produced by trainees in the partnering organizations.

NOBARRIERSHED

A prefabricated, flat-pack deployable shed with reclaimed solid-core doors and church pews.

Two versions of the shed are currently being designed for a local nursery. UDBS students are working on incorporating the reused materials identified by CJ into cladding of the sheds. Development will be picked up by the entrepreneurial arm of PROJECT RE_. Look for the two prototype sheds on sale at CJ soon!

RE_DRESS

A mobile wardrobe and room divider inspired by harvested glass panels and reclaimed white oak lumber.

The goal was to provide comfortable and intuitive features using lo-tech construction processes. During a short charrette in September 2013, the design was developed by UDBS students through full scale prototyping. While custom details differentiate RE_DRESS, it is dependent on strategies that can be replicated efficiently and can be used to teach woodworking skills to others.

Construction documents facilitated coordination with Solid PGH furniture fabricator Matt Robinson for refinement and final production. The RE_DRESS wardrobe will be fabricated on a larger scale and available for purchase as a statement feature for any space.